I’m going to share the process of building a floating mat system, from design to sourcing materials and build. I figured I try to take out as much guess work since I had no guidance and had to learn on my own. There were several pieces of the puzzle that came as some small surprises, but hopefully this helps the next person who decided to make the leap to a better mat system. I’m unsure of the process for other countries, but in my case I will detail the process for importing goods into New Zealand – it may differ in other places. I’ll include links to the factory for all the specific mats I ordered in the post.

Towards the end of Sept 2020, just after the Covid-19 lockdown ended in New Zealand, I had an opportunity to expand my BJJ club and sub-lease space in our existing gym we ran out of. I had an elaborate vision of a floating mat system underneath some juicy dollamur mats for use to train in.

I was introduced to the floating mat system years ago when I lived in Los Angeles on a visit to Kron Gracie’s academy in Culver City. I had worked down the street and wanted to congratulate him and have a look around. My friend Ollie Barre worked there and he showed me around, even Kron said hello and mentioned the spring loaded floating mat system to me.

It was about 1/2 a meter high with actual springs under the floor with plywood on top and tatame on top of the ply. It was amazing!

I knew that’s what I wanted but I didn’t have the budget for springs, so I explored other options. After a few searches I came across a couple videos:

How to build the ultimate spring subfloor for your Judo, Jujitsu and Wrestling mats

&

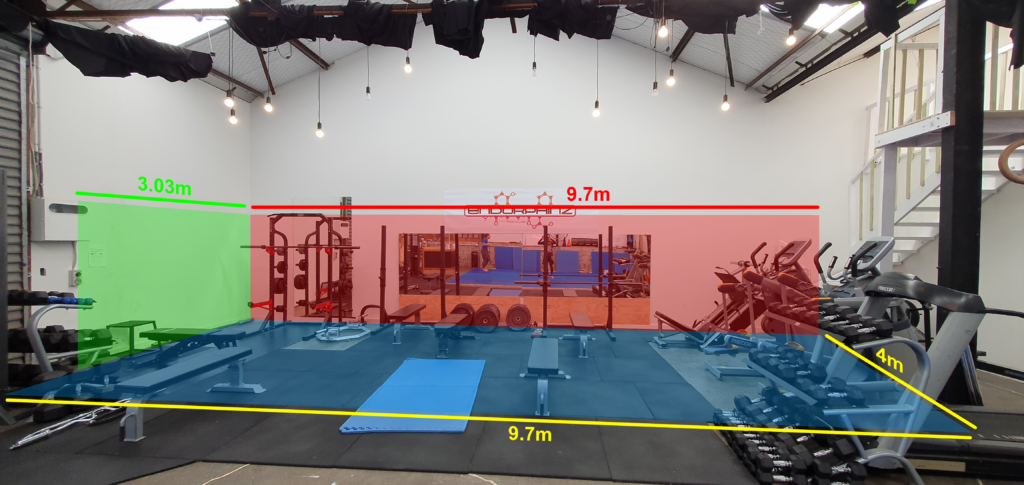

Foam and ply – sweet I can do that! Let’s measure the space:

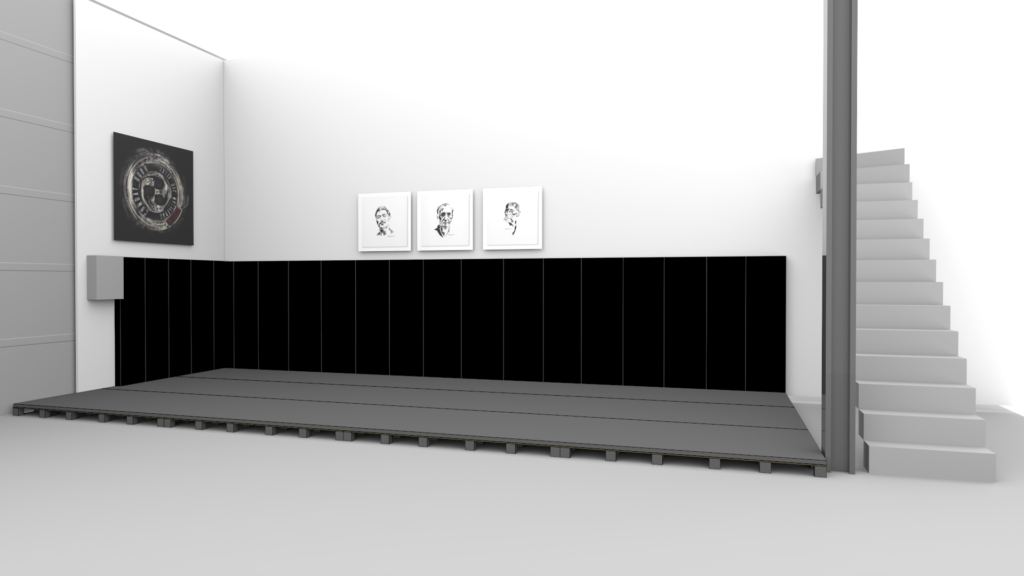

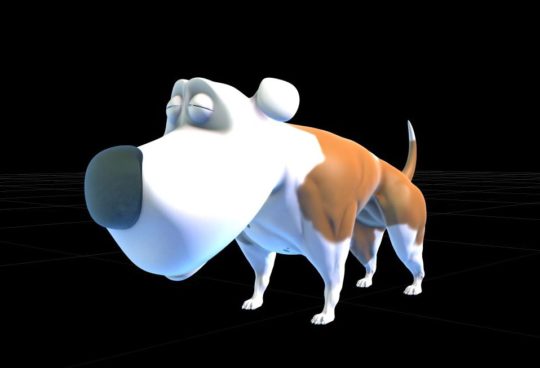

After the measurement I needed to visualize the build. I knew I had to see it and make something for others to see the vision I had, so I modeled everything out in Maya and made a 3D render:

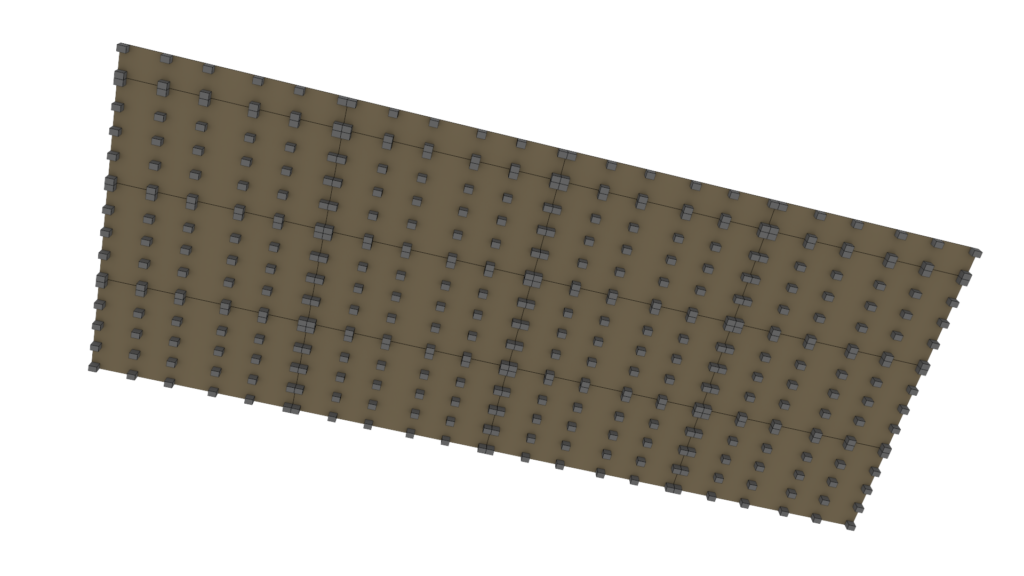

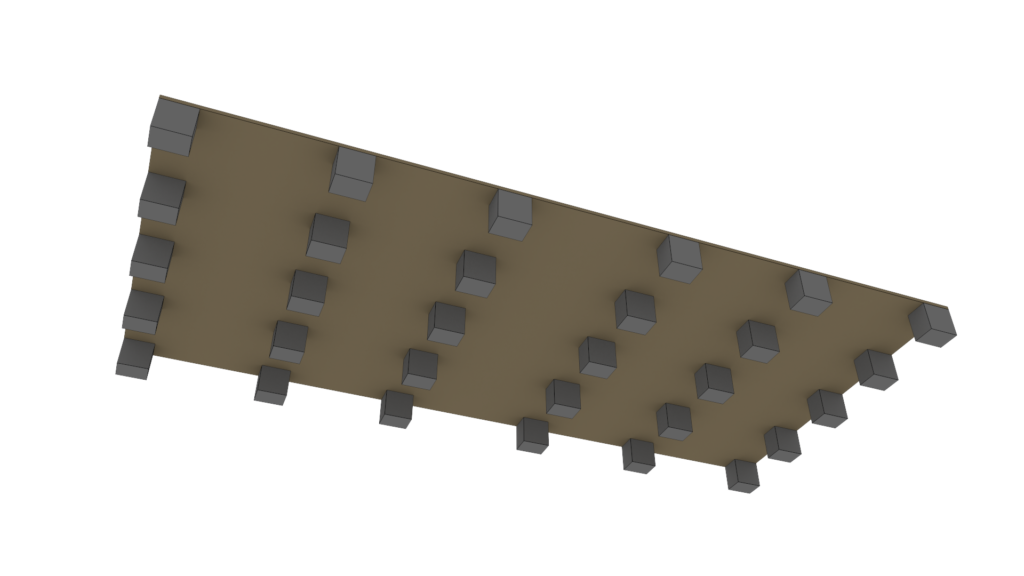

I used real world units to keep everything to spec, that means the units I use in the 3D application are accurate to and equal to the units I would use on the actual build. The sub-floor would be the most difficult thing to explain to a builder, so I did a couple renders of what the underbelly would look like:

I began compiling a list of materials I would need:

- 15 sheets of 2440mm x 1200mm x 12mm non-structural plywood

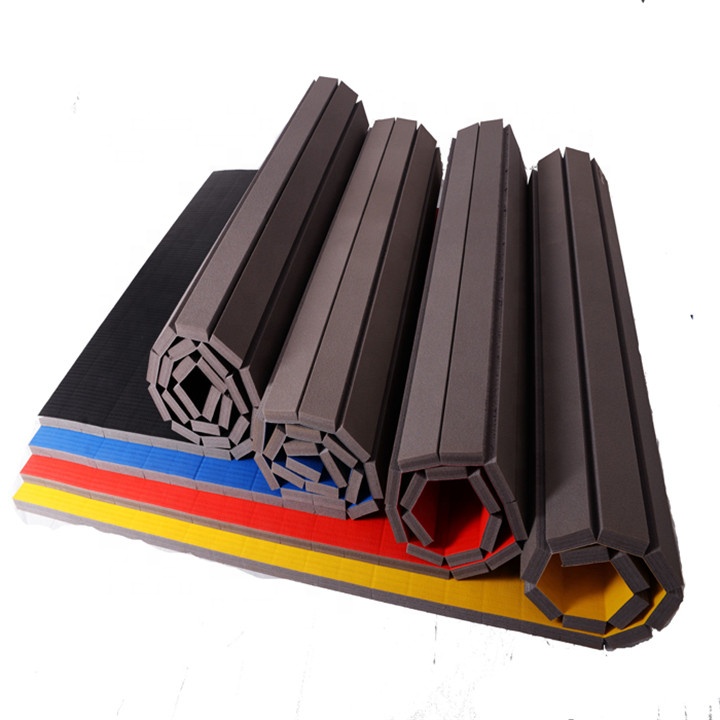

- 6 sheets of closed cell polyethylene foam

- tons of liquid nail

- timber for boxing in – unsure of spec at that time

- 5cm thick floor mats, tatame finish

- 21 wall mats @ 183cm x 122cm x 5cm

Living in New Zealand is awesome BUT sourcing some of these materials was going to be difficult and super expensive. I started calling around and emailing different foam companies and dollamur reps. I was getting quotes just for the dollamur mats of $5-6k NZD alone! I found a company that imports foam and was quoted $500/sheet of PE foam! I didn’t even bother looking at the wall mats – it would have cost me closer to 10K to get everything from NZ companies, so I decided to cut out the middle man and source materials myself.

Of course this lead me to Alibaba.com – the Chinese based website that gives people like myself access to factories where these things are typically made. After a few days of searching and multiple emails, I found a factory – Quindao Sanhong Plastic Co, LTD – that appeared to manufacture everything I needed – floor mats, wall mats and PE foam sheets.

It was my 1st time using Alibaba and to be honest I was SUPER dubious. I would be dealing with people outside of the country I lived in which carries a larger sense of the unknown.

I ended up chatting with a service person named Emily. She was incredibly helpful and thorough and made sure she understood what I required. I sent her an absurd amount of photos, videos, all of my renderings of what I had in mind, the measurements and other specs. She talked me into getting a more dense mat (40kg/cbm – a new unit of measurement I was completely unfamiliar with) for both the floor mats and sub-floor mats.

Originally I intended to have that pool noodle type foam, but Emily urged me not to go that route and go for something thicker – the cost was negligible so I went for it. Trusting someone you’ve never met overseas was hard, but I figured I needed to roll the dice.

The floor mat specs I went with were 3 rolls of 9.7m x 1.33m x 5cm with a tatame finish

Link to mats here

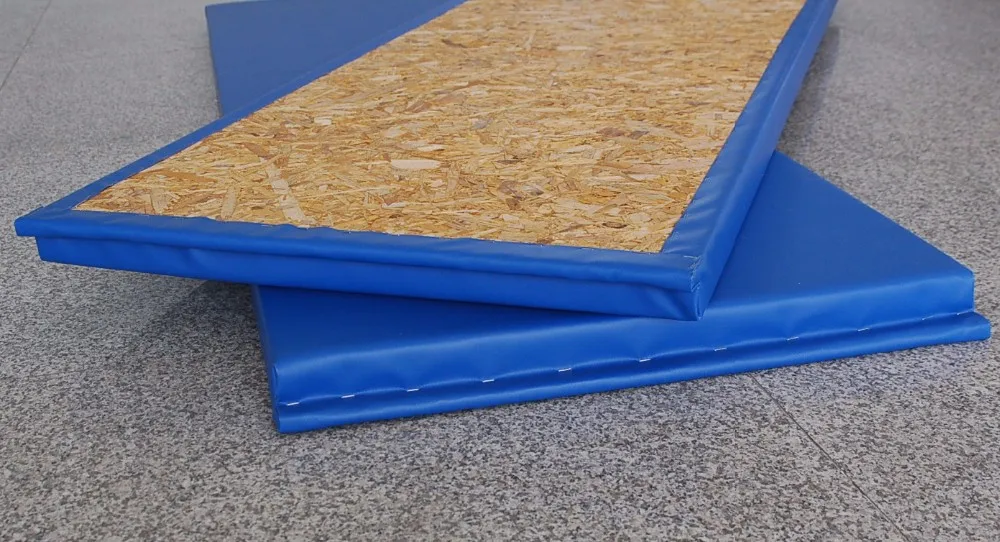

Next were the wall mats. I needed 21 wall mats @ 183cm x 122cm x 5cm

Link to mats here

Next was the closed cell sub-floor PE foam. Quindao made 2m x 1m sheets of this stuff, and I needed 6 sheets total to accommodate my space. These were roughly $40USD / sheet so if I got it wrong I figured it wouldn’t be TOO much of a loss.

Link to foam sheets here

Emily was very patient and understand of my reservations in dealing with an overseas factory. After a few more emails and messages I pulled the trigger and made the order. At this stage Emily walked me through the process and gave me a general idea of several unknown import costs. Her estimate on the NZ import tax was very close, but she did inform me there would be other costs she had no way of providing an estimate for.

I forgot to mention that a couple months prior to ordering I had already setup a legit business in anticipation of building my dream in the future. Emily had requested an NZ Import ID so fortunately I was already qualified to apply for a NZ business import ID through NZ Customs. This cost me about $200 to register my business and get an import ID.

After providing all of my information, she came back with a total cost and import tax estimate I would pay on arrival. Freight costs from China to NZ were SUPER cheap – about $80NZD to ship 700kg worth of stuff, so that was fine.

I paid the deposit so the manufacturing could get under way. Once they were finished making all of the mats/materials I would then pay in full prior to loading onto the ship. It took them about 4 weeks to finish everything. At that time there was one final check through that they had all of my correct information and import ID and that was that. The order started on 11/02/2020 and was shipped on 12/08/2020

Because of Covid, there were huge delays with international shipping and unloading, so the wait time was longer than usual. It was supposed to take 40 days but ended up being much longer than that. The mats arrived in NZ the 1st week of February 2021 – phew at least they made it safe!

This is where a lot of the surprises and unknowns came into play. I received an email from some guy at a freight company saying my mats had arrived and I needed to send all of the arrival documents to my broker

Evidently I had to obtain an import broker to forward all of the documents to, which no one makes any mention of. But here’s where things get a little…rackety. I ended up going with EasyFreight brokers who charged me about $200 for their services. They emailed documents from NZ Customs where I then had to pay around $500NZD for the Import Tax.

Once the Import Tax was paid, my mats could then be released BUT…the mysterious freight company who initially emailed me now says I need to pay them $1900NZD before they ship my mats to Wellington. This fee was for unloading the mats from the ship and onto the dock and storing them in a warehouse until all of the documents cleared. This almost doubled the cost of the mats I ordered and by now the total cost was getting close to what I was getting quotes from NZ based companies.

I paid the invoice and they put my mats onto a truck to be shipped down to Wellington to ANOTHER freight company – not directly to me for whatever dumb reason. I contacted the new freight company, had a bit of confusion and back and forth but eventually I ended up having to pay them another $250NZD to ship my mats to the gym. What a racketeering outfit huh?

They delivered the mats and I immediately started ripping up the packaging to have a look at my new goods. I have to say that what I purchased exceeded my expectations. The floor mats where BETTER than what I expected, the wall mats were BETTER than what I anticipated and the sub-floor foam ended up being more closer to memory foam than pool noodle foam. Holy hell we’re gonna have some sweet mats to roll on!

To the build!

After a trip to Bunnings to pickup timber, liquid nail and a few other things, that tallied up to over $1000NZD we were on our way.

The 1st order of business was to cut the foam sheets into blocks. I had originally calculated 7cm x 10cm x 10 cm but when we laid everything out, we’d only be using 2 sheets of foam and would have had to cut relatively tiny blocks. So instead we went with 20cm x 20cm x 10cm blocks – much easier to cut and deal with and even then we had a ton left over (which we made use of by the end of it.

I worked out the numbers and we did 3 x 5 rows of blocks per plywood sheet

We had all of the blocks glued to the ply and realized we had HEAPS left over, so we decided to re-jig some things around and use the extra blocks in the spaces inbetween sheets of ply on the seams and corners. This ended up adding an extra level of stability between the ply and would be less likely to damage the mats on top.

Once all the plywood was laid out and the liquid nail given a bit of time to cure, we had to then box everything in to prevent sliding. This required a concrete drill/concrete bit, about 10 dynabolts (basically concrete bolts with anchors), some timber 2 x 4s, more liquid nail and a bit of good old fashioned elbow grease.

The guys marked where the holes needed to be drilled roughly 1 1/2 meters apart. After the holes were drilled and swept, we laid down a very long 2×4 that was already predrilled with the initial concrete hole drilling. A dynabolt was hammered into the hole as far as it could, then racheted down with a socket wrench to tighten. The 1st piece of timber would be the foundation the other boxing in pieces would be anchored to.

The farside wall was crooked so that meant our sheets were slightly offset on the outside edge. As long as the surrounding box was square, the top layer mats would hide the crooked ply and we’d be fine.

Timber posts are rather expensive in NZ and usually crooked, so we ended up gluing and screwing 2 2×4 together so that 1. they cost less and 2. we could straighten them much easier.

To secure the 2x4s to the base we used nails and several Stud to Bottom galvanized fixings. We needed to make sure there would be absolutely no flex with the box.

To have a nicer finish, we added a thin layer of finger jointed pine on top of the 2x4s secured with finishing nails. The grain and look of it is much more eye pleasing than the sides of 2x4s and I can stain or paint it later.

We left about a 3cm lip around the box so when the mats sit on top of the ply, the outer frame would contain and lock in the mats from sliding. The mats came very well packaged in three 1.3m x 9.7m x 5cm rolls

We placed extra ply against the walls to create a wedge/spacing for the wall mats. Upon rolling out the 1st roll we realized the wall was not straight…at all, but we made it work. 1st mat down!

The middle roll was relatively easy to to setup and the velcro attachment worked out perfectly.

The final row did prove to be a bit more challenging but we eventually squeezed it into the remaining space. We can do math!!

After a full day of work we got the mats installed. We started at 11am, did a Bunnings run to collect tubes of liquid nail, screws, etc, got to the gym at around 12:30pm and finished just after 1am.

The following weekend we mounted the wall mats which were relatively straight forward. We ran 2 rows of 5m x 18mm pine planks along the wall, one at the top of the wall mats and one mid mat for support. I forgot to take pics but we basically created a support system and something to drill into instead of thick firewall jib.

We finished in the evening, cleaned up and of course we had a roll!

Some after thoughts

I can’t tell you how happy I am with this setup. Having an extra 10cm of foam under the sub floor has made a HUGE difference. It only took about 3 weeks to break in the harshness of new mats, and the tatame finish has been amazing. They aren’t slippery at all and are like heaven to roll on. One thing I would have done, which I most likely will do soon is to place 1 screw into each foam block under the sub floor.

What happens is the vibrations of people moving on the mats will cause the foam blocks to shift if they liquid nail didn’t stick. Not a big deal as we can simply lift the mats/play and move the foam, but that’s the only thing I would have done. Everything else worked out perfectly and I could not be more happy.

I hope this helps anyone who is interested in building something like this. There are a LOT of unknowns that go into importing goods from overseas, but I covered all of the “gotcha” moments along the way. Also I can with full confidence say that Quindao Plastics manufacture high spec and high quality mats/foam. They exceeded my expectations, so you can purchase with confidence. I knew nothing about them, only went by their Trade Assurance certification rating on Alibaba, but who the hell knows what that means? I’m thrilled I rolled the dice – they nailed it!

Reach out if you have any questions

Oss!

Sorry, the comment form is closed at this time.